News Center

What is the working principle of an automatic fabric inspection and rolling machine?

Release time:

2023-06-19

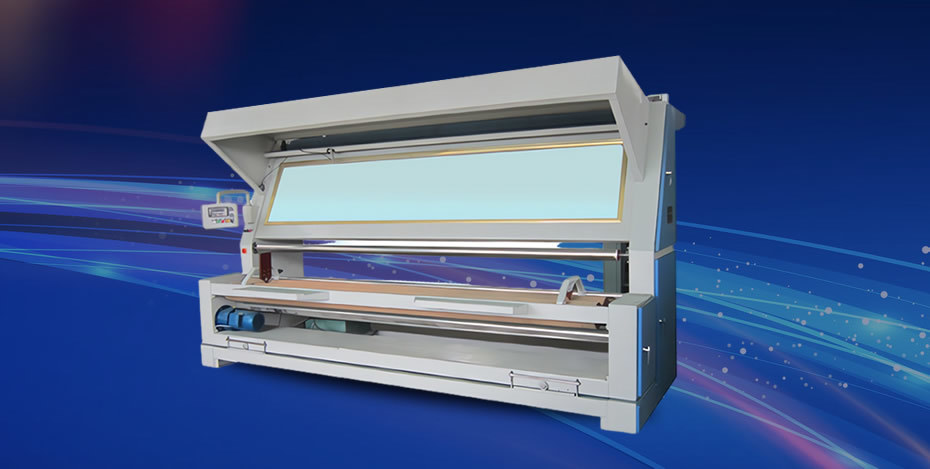

The automatic fabric inspection and rolling machine is a new type of equipment that can greatly improve the production efficiency and product quality of factories. Below, we will provide a detailed introduction to the automatic fabric inspection and rolling machine.

The automatic fabric inspection and rolling machine is a new type of equipment that can greatly improve the production efficiency and product quality of factories. Below, we will provide a detailed introduction to the automatic fabric inspection and rolling machine.

1. Working Principle of the Automatic Fabric Inspection and Rolling Machine

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, which can quickly and accurately detect the quality and defects of the fabric and classify them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism that can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2. Advantages of the Automatic Fabric Inspection and Rolling Machine

1. High Efficiency: The working speed of the automatic fabric inspection and rolling machine is very fast, capable of completing the inspection and rolling of dozens of fabric pieces in a minute. It can also automatically identify the quality and defects of the fabric, avoiding manual misjudgment and improving work efficiency.

2. Accuracy: The automatic fabric inspection and rolling machine uses advanced photoelectric detection technology, which can detect the quality and defects of the fabric with high precision, ensuring very high accuracy.

3. Labor Savings: The automatic fabric inspection and rolling machine can automatically complete the tasks of fabric inspection and rolling, reducing manual operations and saving labor.

4. Improved Working Environment: The rolling mechanism of the automatic fabric inspection and rolling machine adopts a closed design, which can reduce noise and dust generation, improving the working environment.

5. Improved Product Quality: The automatic fabric inspection and rolling machine can quickly and accurately detect the quality and defects of the fabric, preventing the production of substandard products and improving product quality.

3. Applicable Scope of the Automatic Fabric Inspection and Rolling Machine

Currently, the automatic fabric inspection and rolling machine has been widely used in industries such as textiles, clothing, and home furnishings. Especially in the textile industry, the application of the automatic fabric inspection and rolling machine has become a trend, significantly improving the efficiency and quality of fabric inspection and rolling, making production more intelligent and automated.

4. Market Prospects of the Automatic Fabric Inspection and Rolling Machine

The emergence of the automatic fabric inspection and rolling machine fills the gaps of traditional inspection methods, greatly improving work efficiency and product quality. It is foreseeable that with the continuous improvement of the intelligence and automation level of the manufacturing industry, the market prospects for the automatic fabric inspection and rolling machine will become increasingly broad.

Key words:

Related News

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18