News Center

How to choose different types of roll fabric machines?

Release time:

2024-04-18

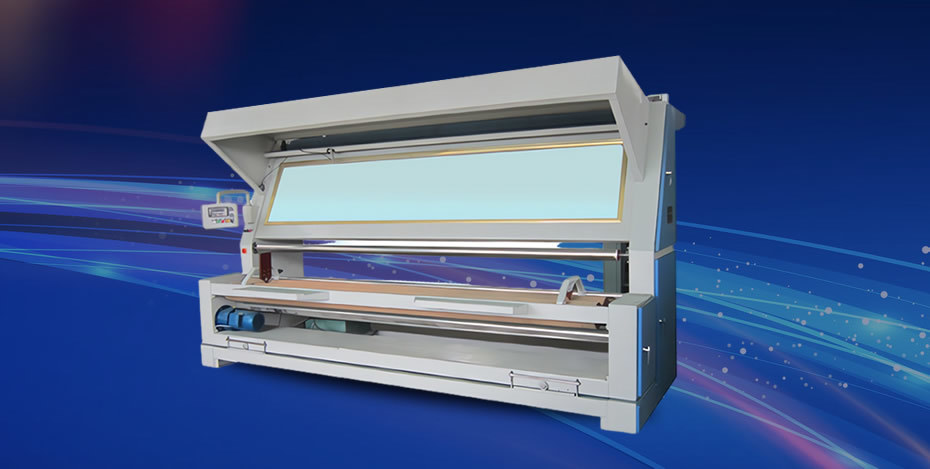

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

In order to improve production efficiency and reduce labor costs, garment factories can selectively choose different types of fabric rolling machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment fabric rolling machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

Fabric inspection and rolling machine manufacturers can choose different levels of rolling machines based on product quality requirements. For high-end, high value-added products, high-grade rolling machines can be selected. For example, the no-tension rolling machine from Xiangfengli Machinery Factory introduces advanced technology. For mid to high-end products, mid-range rolling machines can be selected, such as the longitudinal stripe open-width rolling machine. For domestically sold products that are in high demand and widely used, such as pure cotton and synthetic fiber products, a popular type of electric eye automatic edge-alignment rolling machine can be used, which is relatively low in price and easy to promote and apply.

After years of experience from domestic textile machinery manufacturers, the performance of weaving machines is excellent, and their quality can reach internationally advanced levels. The product quality basically meets and adapts to the demands of both domestic and international markets.

Key words:

Related News

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18