News Center

How to operate a trimming machine?

Release time:

2023-06-19

The trimming machine cuts the head of the bolt blank forged by the forging machine into a hexagonal head shape.

The trimming machine cuts the head of the bolt blank forged by the forging machine into a hexagonal head shape.

Advantages:

1. Save on the expensive mold opening costs during sampling;

2. Save on your mold tool costs and mold tool time;

3. Modifying samples is very convenient, just need to modify the electronic document, good flexibility, **;

4. Can complete cutting of any shape, high precision, high quality.

What are the safety operating procedures for the trimming machine?

1. Before starting the equipment, add oil to the hand-operated oil pump as required.

2. Check whether the edge trimming device's brackets are in contact with the bed surface; if not, notify the maintenance worker for repair.

3. When cutting gears, pay attention to whether the adjustment height of the material pull rod is appropriate; if not, it may cause an accident.

4. If the forged blank is too large and the end edge is too long and collides with the bed, do not proceed with trimming.

5. When adjusting the closing height of the slider, pay attention to the scale to avoid exceeding the range.

Key words:

Related News

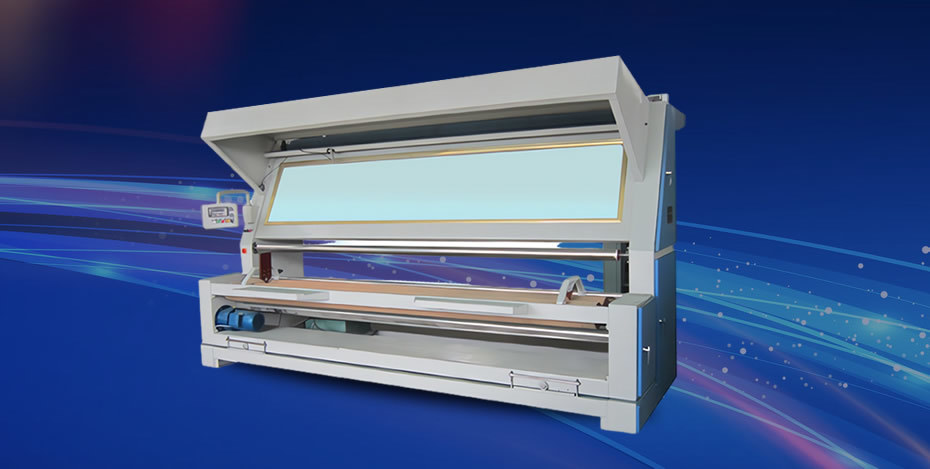

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18