News Center

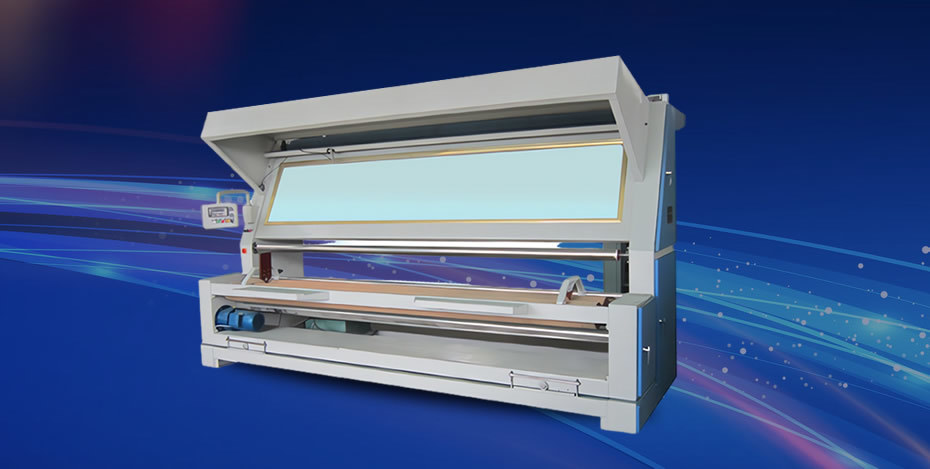

The roll fabric machine is economical, practical, and simple yet not simplistic.

Release time:

2021-11-09

The fabric rolling machine is economical, simple yet not simplistic. Features: Integrated fabric rolling and counting: combines fabric rolling, counting, and checking functions; Flexible speed adjustment: the fabric inspection rolling machine manufacturer uses a speed controller for flexible control of rolling speed; Accurate length measurement: equipped with a meter for accurate measurement of fabric length; Convenient and flexible operation: easy to load fabric, control switch for immediate start and stop; Stable and durable operation: reasonably designed structure, using high-quality components for long-lasting durability; Free adjustment of tightness: uses a tension frame to adjust the tightness of the rolled fabric.

The fabric rolling machine is economical, simple yet not simplistic. Features: Integrated fabric rolling and counting: combines fabric rolling, counting, and checking functions; Flexible adjustable speed: the fabric rolling machine manufacturer uses a speed controller for flexible speed control; Accurate length measurement: equipped with a counting (meter) device to accurately measure the length of the fabric; Convenient and flexible operation: easy to load fabric, control switch can start and stop immediately; Stable and durable operation: reasonably designed structure, using high-quality components for durability; Free adjustment of tightness: uses a tension frame to adjust the tightness of the rolled fabric.

Features of the fabric rolling machine: Integrated fabric rolling and counting: combines fabric rolling, counting, and checking functions;

Flexible adjustable speed: the fabric rolling machine uses a speed controller for flexible speed control;

Accurate length measurement: equipped with a counting (meter) device to accurately measure the length of the fabric;

Convenient and flexible operation: easy to load fabric, control switch can start and stop immediately;

Stable and durable operation: the fabric rolling machine has a reasonably designed structure, using high-quality components for durability; Free adjustment of tightness: uses a tension frame to adjust the tightness of the rolled fabric.

Usage: The fabric rolling machine is widely used in industries such as garment factories, shoe factories, knitting factories, knitted garment factories, and weaving factories for fabric rewinding, measuring, loosening, and rolling.

Applicable scope: The fabric rolling machine is suitable for rolling semi-finished or finished products of woolen, color woven, silk woven, printed, knitted, cotton woven, or other fabrics.

Key words:

Related News

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18