News Center

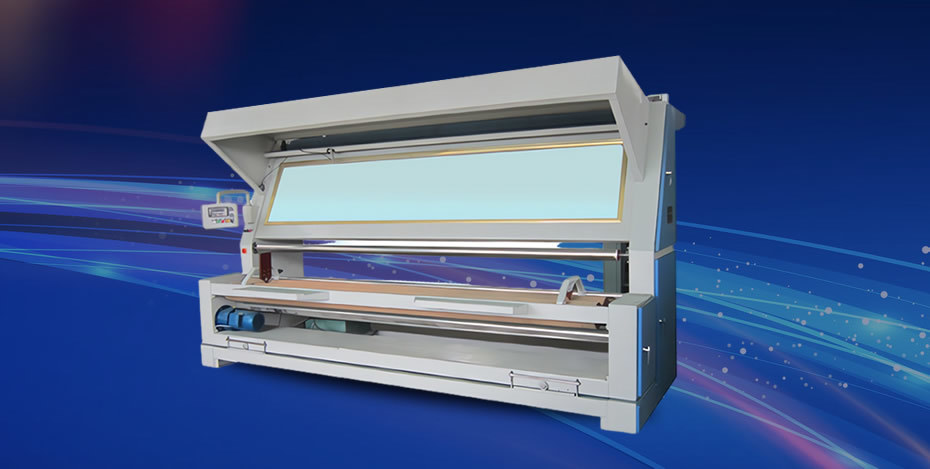

What fabrics are suitable for large roll fabric machines?

Release time:

2024-04-15

As we all know, different products are suitable for different machines. Which fabrics are suitable for large roll fabric machines? The fabrics suitable for large roll fabric machines mainly include: ordinary fabric, non-woven fabric, foam fabric, acetate fabric, conductive fabric, etc. However, the characteristics of these fabrics are also different, so the operating speeds of the machines will vary. For example, when rolling up foam fabric, the large roll fabric machine must operate at a slower speed because foam fabric is very prone to breaking. Familiarity with the characteristics of each type of fabric is also very helpful for using the machines.

As we all know, different products are suitable for different machines. Which fabrics are suitable for large roll fabric winding machines? The fabrics suitable for large roll fabric winding machines mainly include: ordinary fabric, non-woven fabric, foam fabric, acetate fabric, conductive fabric, etc. However, the characteristics of these fabrics are also different, so the operating speed of the machines varies. For example, when winding foam fabric, the large roll fabric winding machine must operate at a slower speed because foam fabric is very prone to breaking. Familiarity with the characteristics of each type of fabric is very helpful for using the machines.

In fact, different fabrics require different types of winding machine spindles. This is mainly due to the differences in fabric density and weight. Generally, manufacturers tend to use a single type of spindle when operating winding machines, which is not recommended. When purchasing a winding machine, it is essential to operate according to the correct usage specifications to avoid unnecessary damage to the machine itself, while also protecting oneself is crucial.

The successive emergence of large roll fabric winding machines has attracted a lot of attention, indicating that the invention of large roll fabric winding machines is very significant. The profit margins in the textile industry are sometimes very low, so it is necessary to improve the production speed of products.

Key words:

Related News

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18