News Center

What is the significance of using an automatic fabric cutting machine?

Release time:

2024-04-17

In the increasingly competitive apparel and textile industry, how to take the lead and surpass competitors has become a major issue for enterprises, especially how to break through the fierce market competition. It is particularly important to systematically control the quality, cost, and efficiency of finished products.

Many people have a question, why use an automatic fabric cutting machine?

In the increasingly competitive garment and textile industry, how to get ahead and surpass competitors has become a major issue for enterprises, especially how to break through the fierce market competition and systematically control the quality, cost, and efficiency of finished products is particularly important.

In the cutting process, using an automatic fabric cutting machine can effectively ensure the quality of the finished product, reduce costs, and improve efficiency.

From the perspective of efficiency, compared to manual labor, machines do not feel tired, do not need rest, can operate efficiently for long periods, and can maintain quality. From the cost perspective, manual fabric handling requires more personnel coordination and operation, leading to higher labor costs, while an automatic fabric cutting machine only requires one person to operate and one person to assist, which saves costs while also increasing efficiency. Regarding quality, the effect of fabric handling before cutting directly affects the quality of the finished garment; if defective products are discovered only after cutting, the impact is irreparable, and using an automatic fabric cutting machine can solve this problem.

Key words:

Related News

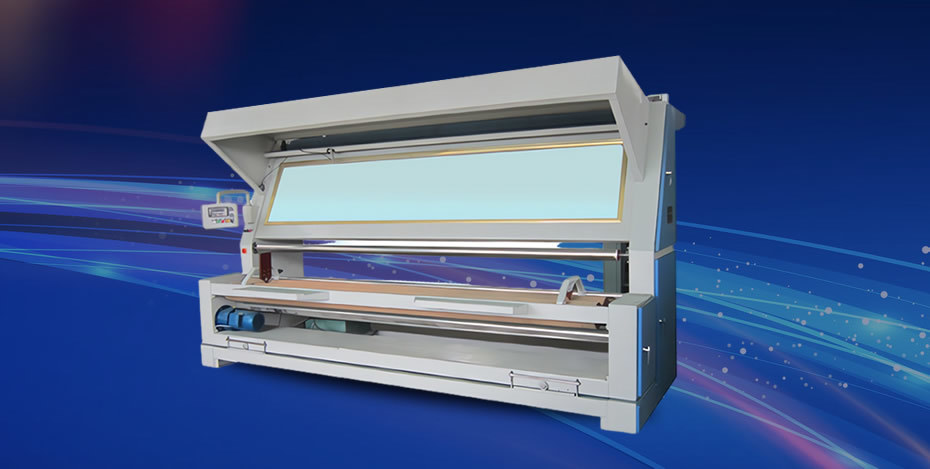

What is the working principle of an automatic fabric inspection and rolling machine?

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024-04-19

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024-04-18